Single row deep groove ball bearings

It is characterized by low friction resistance and high speed. It can be used for mechanical parts that bear radial loads at the same time or combined radial and axial loads.

Category:

Single row deep groove ball bearings

Key words:

Single row deep groove ball bearings

Product Description

Deep groove ball bearings (gb/t 276-1994), formerly listed as radial ball bearings, are the most widely used rolling bearings. It is characterized by low friction resistance and high speed. It can be used for mechanical parts that bear radial loads at the same time or combined radial and axial loads. It can also be used for mechanical parts that bear axial load, such as small power motors, automobile and tractor gearboxes, machine tool gearboxes, general machines, tools, etc.

In mechanical engineering, double-row deep groove ball bearings stand out for combining deep groove ball bearing reliability with enhanced load capacity. Conforming to GB/T 276-1994, they handle radial and axial loads effectively, making them ideal for diverse industrial applications.

The Foundation of Design: Structure and Standards

These bearings feature two rows of precision balls in a single outer ring with dual inner rings (or split inner ring), separated by a cage for optimal spacing. Based on single-row radial ball bearings, the design doubles contact points for improved load distribution. The GB/T 276-1994 standard ensures consistent dimensions, materials, and tolerances, guaranteeing precision and durability.

Key Advantages for Diverse Load Scenarios

Double-row deep groove ball bearings manage complex loads by handling heavy radial loads and moderate axial loads in both directions. The deep-groove raceway design distributes stress evenly, reducing concentration and preventing premature failure under misalignment or shock loads. This versatility suits gearboxes, pumps, and conveyor systems with combined load requirements.

Low Friction Resistance for High-Speed Efficiency

Precision-finished raceways and smooth balls minimize frictional losses, critical for high-speed applications like electric motors. Reduced friction lowers energy waste and heat generation, maintaining operational temperatures and extending component life. This efficiency supports consistent rotational speeds and reduces maintenance intervals in industrial tools and small motors.

High Speed Capability for Dynamic Operations

Balanced design and rigid construction enable sustained high speeds without compromising load capacity. Lightweight cages prevent ball skidding, ensuring stability in automotive transmissions and other dynamic systems. The combination of speed and reliable load distribution meets the demands of fast-paced manufacturing and transportation.

Applications Across Industries

Automotive: Used in gearboxes, wheel hubs, and engines to handle radial/axial loads and varying speeds.

Industrial Machinery: Supports heavy radial loads in machine tool gearboxes and enhances efficiency in pumps/blowers.

Electrical Equipment: Improves motor efficiency through low friction and high-speed performance.

General Machinery: Provides stability for conveyor systems and woodworking tools under off-center loads.

Maintenance and Installation Simplicity

Pre-lubricated models reduce maintenance needs, while sealed/shielded variants protect against contaminants. Simple alignment and standard fitting make installation easy for new equipment and replacements, extending service life in harsh environments.

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

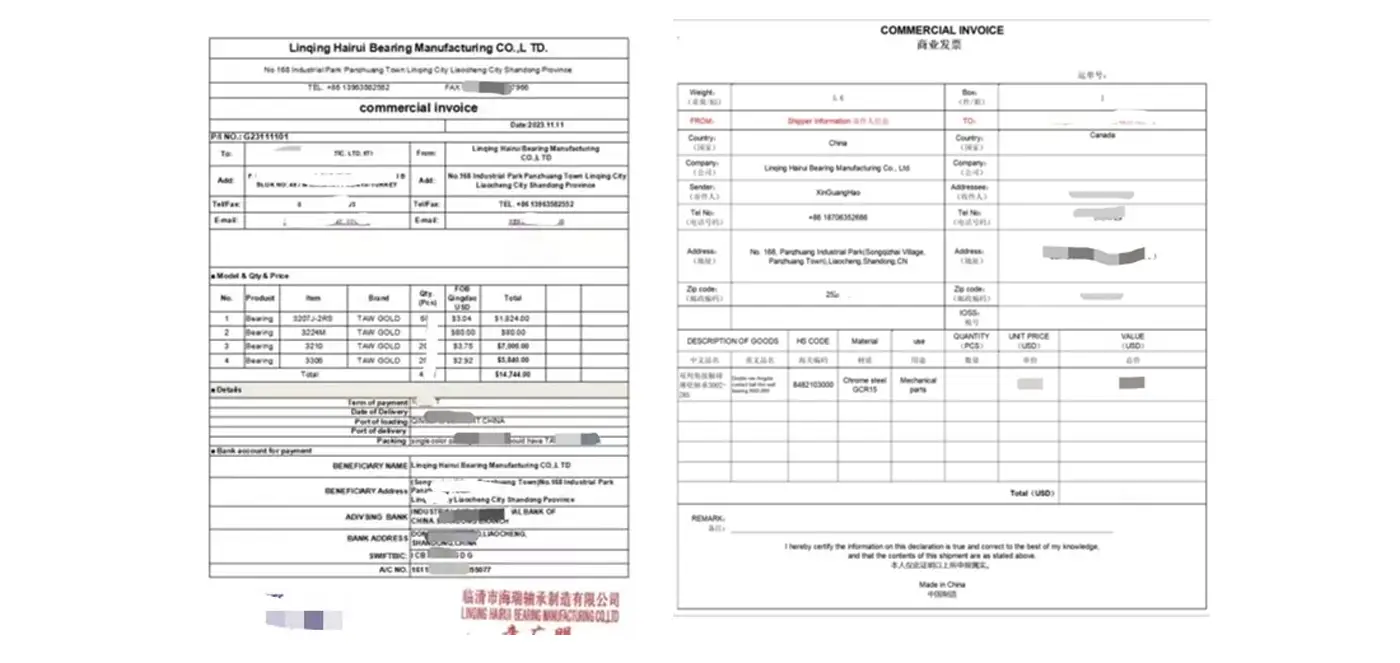

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE