Linear Motion Bearings LME.UU

LME.UU This type is metric dimension series generally used in Europe. LM/LME linear bushing has a steel outer ring with grooves for a circlip and a polyamide ball retainer with 3 to 6 ball circuits depending on size. On request linear ball bushing are also available in stainless steel. All linear bearings with the designation UU have seals from both sides.

Category:

Linear Motion Bearings

Key words:

Linear Motion Bearings

Product Description

Product Details

LME.UU

This type is metric dimension series generally used in Europe.

LM/LME linear bushing has a steel outer ring with grooves for a circlip and a polyamide ball retainer with 3 to 6 ball circuits depending on size.

On request linear ball bushing are also available in stainless steel. All linear bearings with the designation UU have seals from both sides.

Bearing Model | d(mm) | D(mm | L(mm) |

LME8UU | 8 | 16 | 25 |

LME12UU | 12 | 22 | 32 |

LME16UU | 16 | 26 | 36 |

LME20UU | 20 | 32 | 45 |

LME25UU | 25 | 40 | 58 |

LME30UU | 30 | 47 | 68 |

LME40UU | 40 | 62 | 80 |

LME50UU | 50 | 80 | 100 |

LME60UU | 60 | 90 | 125 |

LME80UU | 80 | 120 | 168 |

Linear motion roller bearings stand as indispensable elements in the intricate world of mechanical engineering, revolutionizing the way linear movement is achieved across diverse industrial landscapes. These bearings are engineered to deliver unparalleled performance, ensuring smooth, efficient, and accurate linear motion in a multitude of applications.

The construction of linear motion roller bearings is a testament to innovative design principles. Unlike traditional bearing types, their utilization of cylindrical rollers is a game-changer. By replacing balls with these rollers, the contact area between the moving parts is increased, significantly reducing friction. This design feature not only enhances the load-carrying capacity of linear motion roller bearings but also minimizes energy losses during operation. As a result, machinery equipped with these bearings can handle heavy loads while maintaining high levels of efficiency, making them a preferred choice for industries where precision and power are both essential.

In manufacturing plants, linear motion roller bearings play a pivotal role in the operation of conveyor systems, machine tools, and automated production lines. They enable the seamless movement of heavy components and workpieces, facilitating rapid production cycles without compromising on accuracy. In the aerospace industry, where every component must meet the strictest standards of performance and reliability, these bearings are used in critical applications such as aircraft landing gear systems and wing flap mechanisms. Their ability to withstand extreme loads and harsh operating conditions ensures the safety and functionality of aircraft during flight and landing.

The durability of linear motion roller bearings is another key attribute that sets them apart. Crafted from premium-grade materials like stainless steel and chrome steel, these bearings offer exceptional resistance to corrosion, abrasion, and fatigue. Many models also incorporate advanced sealing and shielding technologies, safeguarding the internal rollers from dust, moisture, and other contaminants. This protection not only extends the service life of the bearings but also reduces the frequency of maintenance, resulting in lower operational costs for end-users.

Installation of linear motion roller bearings is designed to be straightforward and hassle-free. With standardized mounting interfaces and pre-engineered configurations, they can be quickly integrated into new or existing machinery setups. The availability of pre-lubricated options further simplifies the installation process, eliminating the need for immediate on-site lubrication. However, for optimal performance, it is recommended to conduct regular inspections to check for any signs of wear or damage and perform necessary maintenance tasks as per the manufacturer's guidelines.

When it comes to selecting the right linear motion roller bearings for a specific application, several factors must be carefully evaluated. Load requirements, including static and dynamic loads, are crucial considerations. The operating speed of the machinery, the required level of precision, and the environmental conditions such as temperature and humidity all influence the choice of bearings. By precisely matching the bearing specifications to the application needs, engineers can ensure that the machinery operates at peak performance, reducing the risk of breakdowns and enhancing overall productivity.

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

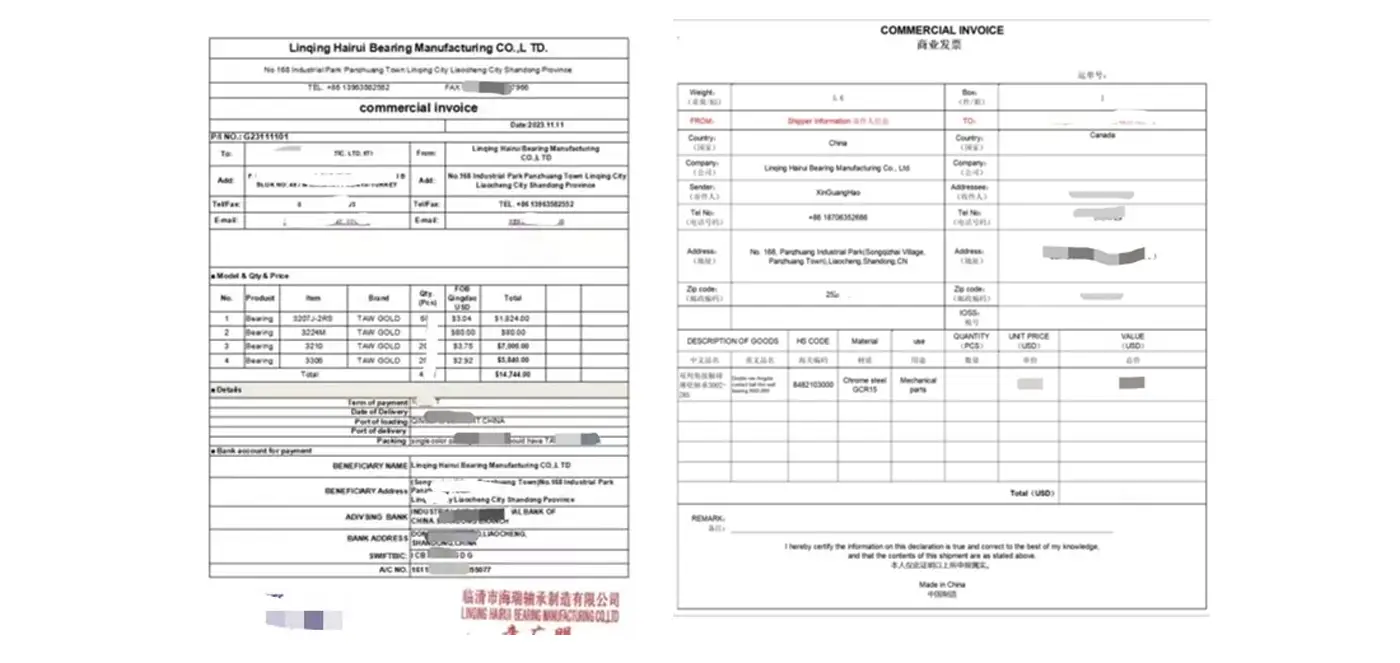

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE