Angular Contact Ball Bearings 70000C Series

Angular contact bearing balls (type 70000 C) with α=15° can bear unidirectional axial load. When bearing pure radial load, bearings must be installed and used in pairs, because the action line of rolling element load and the action line of radial load are not in the same plane, resulting in internal separation force.

Category:

Angular Contact Ball Bearings

Key words:

Angular Contact Ball Bearings

Product Description

Product Details

Angular contact bearing balls (type 70000 C) with α=15° can bear unidirectional axial load. When bearing pure radial load, bearings must be installed and used in pairs, because the action line of rolling element load and the action line of radial load are not in the same plane, resulting in internal separation force.

Bearing Number | d mm | D mm | B mm |

7200C | 10 | 30 | 9 |

7201C | 12 | 32 | 10 |

7202C | 15 | 35 | 11 |

7203C | 17 | 40 | 12 |

7204C | 20 | 47 | 14 |

7205C | 25 | 52 | 15 |

7206C | 30 | 62 | 16 |

7207C | 35 | 72 | 17 |

7208C | 40 | 80 | 18 |

7209C | 45 | 85 | 19 |

7210C | 50 | 90 | 20 |

7211C | 55 | 100 | 21 |

7212C | 60 | 110 | 22 |

7213C | 65 | 120 | 23 |

7214C | 70 | 125 | 24 |

Angular contact ball bearings are a vital component in a wide range of mechanical systems, designed to handle both radial and axial loads with remarkable efficiency. These bearings play a crucial role in ensuring smooth operation, reducing friction, and enhancing the overall performance of machinery.

Structure and Working Principle

At the heart of an angular contact ball bearing lies its unique design. The bearing consists of an inner ring, an outer ring, a set of balls, and a cage. What sets angular contact ball bearings apart is the contact angle between the balls and the raceways. This angle, typically ranging from 15 to 40 degrees, enables the bearing to effectively distribute and withstand combined loads. When a radial load is applied, an axial component is generated due to the angular contact. As a result, these bearings are often used in pairs or multi-bearing sets to counteract the axial forces and maintain stability.

Key Features

Combined Load Capacity: Angular contact ball bearings excel in handling both radial and axial loads simultaneously. The larger the contact angle, the greater the bearing's ability to withstand axial loads. For instance, bearings with a 40-degree contact angle can handle substantial axial forces, making them suitable for applications with high thrust loads.

High-Speed Performance: Thanks to their precision-engineered components and low-friction design, angular contact ball bearings can operate at high speeds with minimal heat generation and vibration. This makes them ideal for applications such as high-speed motors, spindles in machine tools, and aerospace equipment.

Precision and Accuracy: These bearings are manufactured to tight tolerances, ensuring high running accuracy. This precision is essential in applications where precise positioning and smooth rotation are critical, such as in optical equipment and medical devices.

Variety of Contact Angles: Angular contact ball bearings are available in different contact angles, allowing engineers to select the most suitable bearing for a specific application. Smaller contact angles, around 15 degrees, are better for high-speed rotation with relatively light axial loads, while larger contact angles are designed for heavier axial loads.

Applications

Machine Tools: In the manufacturing industry, angular contact ball bearings are widely used in machine tool spindles. Their ability to handle high-speed rotation and combined loads ensures precise machining operations, resulting in high-quality finished products.

Automotive Industry: They are employed in automotive applications such as wheel hubs, transmissions, and electric power steering systems. In wheel hubs, angular contact ball bearings support the weight of the vehicle while allowing for smooth rotation and handling of both radial and axial forces generated during driving.

Aerospace: In aircraft engines and landing gear systems, angular contact ball bearings are crucial for withstanding extreme loads and operating at high speeds in harsh environments. Their reliability and high-performance characteristics are essential for ensuring the safety and efficiency of aircraft.

Industrial Equipment: Angular contact ball bearings are found in various industrial equipment, including pumps, compressors, and conveyors. In pumps, they help to support the rotating shaft and handle the axial thrust caused by the fluid flow, ensuring reliable operation.

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

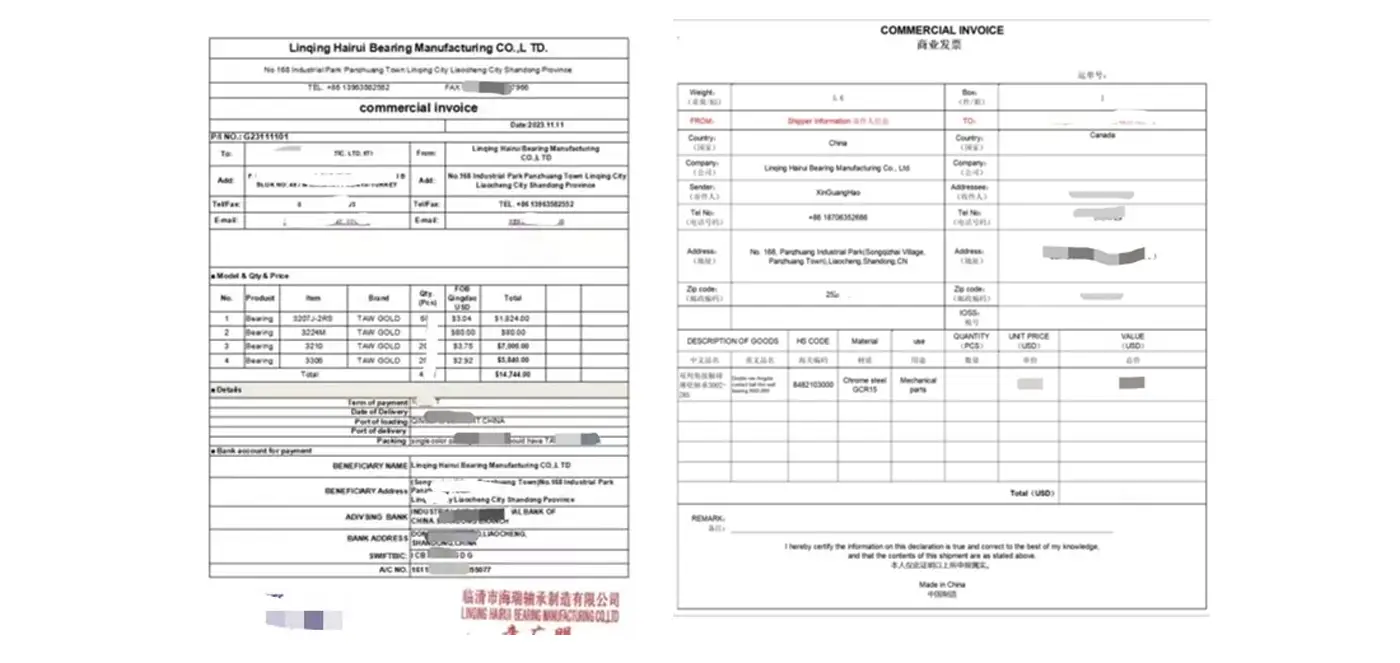

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE