Self-aligning Ball Bearings 1300 Series

1300 Series Self-aligning ball bearings feature: Excellent high-speed performance Accommodate static and dynamic misalignment Low friction Excellent light load performance

Category:

Self-aligning Ball Bearings

Key words:

Self-aligning Ball Bearings

Product Description

Product Details

1300 Series Self-aligning ball bearings feature:

Excellent high-speed performance

Accommodate static and dynamic misalignment

Low friction

Excellent light load performance

Bearing Number | d mm | D mm | B mm |

1300 | 10 | 35 | 11 |

1301 | 12 | 37 | 12 |

1302 | 15 | 42 | 13 |

1303 | 17 | 47 | 14 |

1304 | 20 | 52 | 15 |

1305 | 25 | 62 | 17 |

1306 | 30 | 72 | 19 |

1307 | 35 | 80 | 21 |

1308 | 40 | 90 | 23 |

1309 | 45 | 100 | 25 |

1310 | 50 | 110 | 27 |

Self-aligning ball bearings for conveyors are specifically engineered to address the unique challenges that conveyor systems face. Conveyors often operate in environments where misalignment can occur due to various factors, such as installation errors, vibrations, or thermal expansion. Our 1300 Series Self-aligning Ball Bearings are built with the ability to accommodate both static and dynamic misalignment. This feature is invaluable as it allows the bearings to maintain optimal performance even when the conveyor shafts are not perfectly aligned, preventing premature wear and tear and reducing the risk of system breakdowns. By minimizing the impact of misalignment, these bearings contribute significantly to the extended lifespan of the conveyor system.

High-speed performance is another key aspect that sets our self-aligning ball bearings apart. Conveyor systems are frequently required to operate at high speeds to meet production demands. The 1300 Series Self-aligning Ball Bearings offer excellent high-speed performance, ensuring that the conveyors can run smoothly and continuously without compromising on efficiency. Their design enables them to handle the increased rotational speeds while maintaining stability and reducing noise. This high-speed capability not only boosts the productivity of the conveyor but also enhances the overall operational efficiency of the entire production line.

Friction is a common enemy in conveyor systems as it can lead to energy loss and increased maintenance costs. Our self-aligning ball bearings for conveyors are engineered with low friction in mind. The advanced manufacturing techniques and high-quality materials used in the production of the 1300 Series Self-aligning Ball Bearings minimize friction, allowing the conveyor to operate with less energy consumption. Lower friction also means less heat generation, which further reduces the risk of component damage and extends the service life of the bearings. This energy-efficient design not only saves costs but also makes the conveyor system more environmentally friendly.

In many conveyor applications, the loads can vary, and light loads are often common. Our 1300 Series Self-aligning Ball Bearings shine in such situations with their excellent light load performance. They are able to handle light loads with ease, providing smooth rotation and precise control. This feature is especially important in conveyor systems where delicate or lightweight products are being transported, ensuring that the items are moved safely without any damage. Whether it's a small-scale conveyor in a packaging facility or a large industrial conveyor in a manufacturing plant, our self-aligning ball bearings can adapt to different load conditions and maintain consistent performance.

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

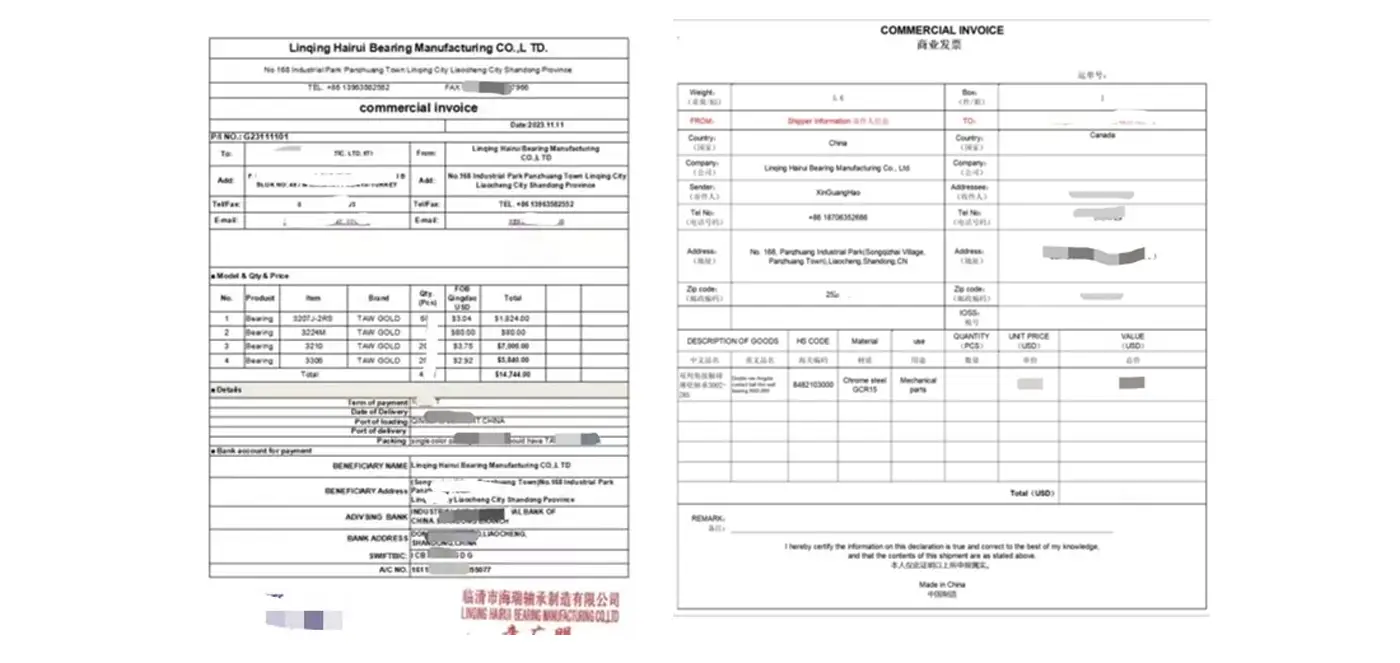

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE