Linear Motion Bearings LM.LUU

LM..LUU(Long Type) This type is a metric dimension series widely used in Asia. The long type linear bearing carries heavier load and guides better than the standard type. Containing two units of the standard retainer plate, this type is optimal for locations where a moment load is present and reduces man-hours in installation.

Category:

Linear Motion Bearings

Key words:

Linear Motion Bearings

Product Description

Product Details

LM..LUU(Long Type)

This type is a metric dimension series widely used in Asia.

The long type linear bearing carries heavier load and guides better than the standard type.

Containing two units of the standard retainer plate, this type is optimal for locations where a moment load is present and reduces man-hours in installation.

Bearing Model | d(mm) | D(mm) | L(mm) |

LM6LUU | 6 | 12 | 35 |

LM8LUU | 8 | 15 | 45 |

LM10LUU | 10 | 19 | 55 |

LM12LUU | 12 | 21 | 57 |

LM13LUU | 13 | 23 | 61 |

LM16LUU | 16 | 28 | 70 |

LM20LUU | 20 | 32 | 80 |

LM25LUU | 25 | 40 | 112 |

LM30LUU | 30 | 45 | 123 |

LM35LUU | 35 | 52 | 135 |

LM40LUU | 40 | 60 | 154 |

LM50LUU | 50 | 80 | 192 |

LM60LUU | 60 | 90 | 211 |

Linear motion roller bearings are essential components in modern machinery and equipment, providing smooth, efficient, and precise linear movement. These bearings play a crucial role in various industries, from manufacturing and automation to aerospace and robotics, where reliable linear motion is required for optimal performance.

At the heart of linear motion roller bearings is their unique design, which allows them to handle high loads and resist wear and tear. Unlike traditional ball bearings, roller bearings use cylindrical rollers instead of balls to reduce friction and increase load-carrying capacity. This design feature enables linear motion roller bearings to support heavy loads with minimal energy consumption, making them ideal for applications that demand high precision and efficiency.

One of the key advantages of linear motion roller bearings is their ability to provide smooth and consistent linear movement. The rollers in these bearings roll along the raceways, minimizing friction and reducing the risk of sticking or jamming. This results in a more stable and reliable linear motion, which is essential for applications that require accurate positioning and repeatability.

Another important feature of linear motion roller bearings is their durability and long service life. These bearings are typically made from high-quality materials, such as stainless steel or chrome steel, which offer excellent resistance to corrosion and wear. Additionally, many linear motion roller bearings are designed with sealed or shielded configurations to protect the rollers from contaminants and debris, further extending their lifespan.

In terms of installation and maintenance, linear motion roller bearings are relatively easy to install and require minimal upkeep. Most bearings are designed to be mounted directly onto a shaft or housing, and many come with pre-lubricated rollers to reduce the need for frequent lubrication. Regular inspection and cleaning of the bearings can help to ensure their optimal performance and prevent premature failure.

When choosing linear motion roller bearings for a specific application, several factors need to be considered, including load capacity, speed, accuracy, and operating environment. It is important to select bearings that are rated for the specific load and speed requirements of the application to ensure reliable performance and prevent damage to the equipment. Additionally, the operating environment, such as temperature, humidity, and exposure to contaminants, should also be taken into account when choosing the appropriate bearings.

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

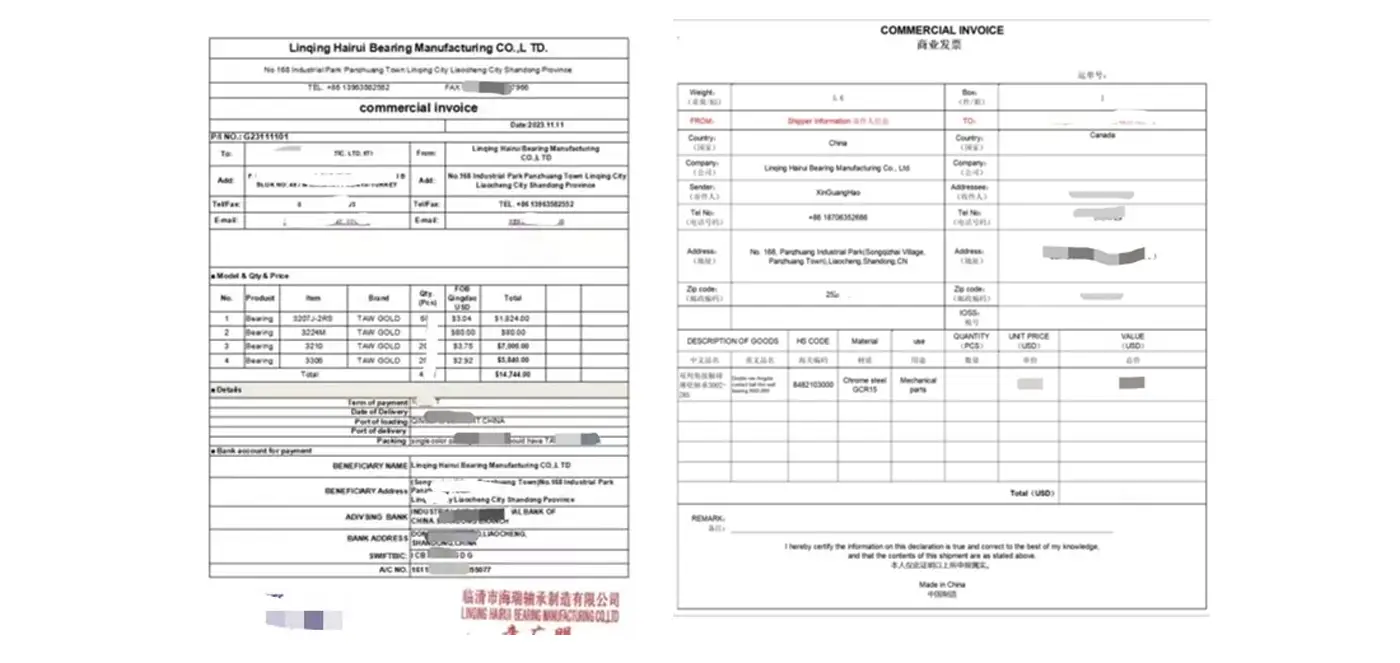

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE