Imperial Four Column

The inch four-row tapered roller bearing is one of the main roller bearings. This type of bearing has a large radial and axial capacity, and the radial load capacity is about three times that of a single-row tapered roller bearing. It can withstand large bidirectional axial loads, but the limit speed is low. It can limit the axial displacement of the shaft (or housing) in both directions within the range of the bearing axial clearance, so it can be used for bidirectional shaft positioning. The diameter and axial clearance of the bearing can be adjusted by changing the thickness of the spacer between the inner and outer rings. Mainly used for the work rolls of hot rolling mills and cold rolling mills, as well as the rolls of blasting machines.

Category:

Tapered Roller Bearings

Key words:

Tapered Roller Bearings

Product Description

Product Details

The inch four-row tapered roller bearing is one of the main roller bearings. This type of bearing has a large radial and axial capacity, and the radial load capacity is about three times that of a single-row tapered roller bearing. It can withstand large bidirectional axial loads, but the limit speed is low. It can limit the axial displacement of the shaft (or housing) in both directions within the range of the bearing axial clearance, so it can be used for bidirectional shaft positioning. The diameter and axial clearance of the bearing can be adjusted by changing the thickness of the spacer between the inner and outer rings. Mainly used for the work rolls of hot rolling mills and cold rolling mills, as well as the rolls of blasting machines.

|

Bearing Number |

Dimensions(mm) |

|

4T-HM903249/HM903210 |

44.45×95.25×30.958 |

|

48680DW/4862/48620D |

139.725×200.05×160.338 |

|

47T563927AWH/DPGC |

229.4×393.7×269.875 |

|

47T513627AWF/DPGCS |

254×358.775×269.875 |

|

511860 |

279.4×393.7×269.875 |

|

532968 |

355.6×457.2×252.413 |

|

EE127097D/EE127135-127136D |

241.478×349.148×228.6 |

|

EE231475D/EE231975-231976D |

374.65×501.65×260.35 |

|

EE531201D/EE300/301XD |

508×762×463.44 |

|

EE649241DW/EE649310/64 |

609.6×787.4×361.95 |

|

EE655271W/EE345/346D |

685.8×876.3×355.6 |

|

EE65527W/EE345/346D/P |

685.8×876.3×355.6 |

|

HM259049D/10/10D |

317.5×447.675×327.025 |

|

HM266449DW/HM266410-HM266410CD |

384.175×546.1×400.05 |

|

K18790/K18720B+K28580/K28521/D |

50.8×92.075×54.381 |

|

KHM218248/KHM218210/DB |

90×147×127 |

|

K387A/K382B+K3979/K3920/DB |

96.838×112.712×61.925 |

|

K95525/K5925-3 |

133.35×234.95×63.5 |

|

KEE127097D/K127135-K127136D |

241.478×349.148×228.6 |

|

KEE135111DW/K135155-135156D |

279.4×393.7×269.875 |

|

LM239530T/46TD/49T/1 |

181.808×259.969×161.925 |

|

LM247748D/10/10D |

244.475×327.025×193.675 |

|

LM247748DW/10/10D |

244.475×327.025×193.675 |

|

LM247748DW/LM247710-LM247710D |

244.475×327.025×193.675 |

|

LM451349DW/10/10D |

266×355×228.6 |

|

LM451349DW/310/310D |

266.7×355.6×228.6 |

|

LM451349DW/LM451310-LM451310D |

266.7×355.6×230.188 |

|

LM761648DW/LM761610-LM761610D |

341.312×457.098×254 |

|

LM761649DW/10/10D |

343.052×457.098×254 |

|

LM761649DW/10/10/HC |

343.052×457.098×254 |

|

LM76164DW/610/610D/P |

343.052×457.098×254 |

|

LM761649DW/LW761610D |

343.052×457.098×254 |

|

LM716649DW/LM761610-LM761610D |

343.052×457.098×254 |

|

LM769349D/LM769310-LM769310D |

431.8×571.5×336.55 |

|

LM274049DW/LM274010-LM2740010D |

508×695.325×419.925 |

|

M238849D/M238810-M238810D |

181.325×269.875×211.138 |

|

M204648DW.611.611D |

198.438×284.163 |

|

M240631T.644T.647T. |

200.819×284.163×239.715 |

|

M249748D/M249710-M249710D |

254×358.775×269.875 |

|

M249710C2/ORM249748D |

254×358.775×289.875 |

|

M252349/M252310-M252310D |

269.875×381×282.575 |

|

M252349/10/10D |

269.875×381×282.58 |

|

M252349D/10/10D |

269.875×381×282.58 |

|

M255449DW/M255410-M25540D |

288.925×406.4×298.45 |

|

M257149DW/110/110D |

304.8×419.1×269.875 |

|

M257248DW/10/10D |

304.902×412.648×266.7 |

|

M257148/M257210-M257210D |

304.902×412.648×266.7 |

|

M274149D/110/110D |

501.65×711.2×520.7 |

|

M274149DW/M274110-M27410D |

501.65×711.2×520.7 |

|

M282249DW/M282210/M2 |

682.7×965.3×701.676 |

AUTOMATIC DETECTION EQUIPMENT

The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

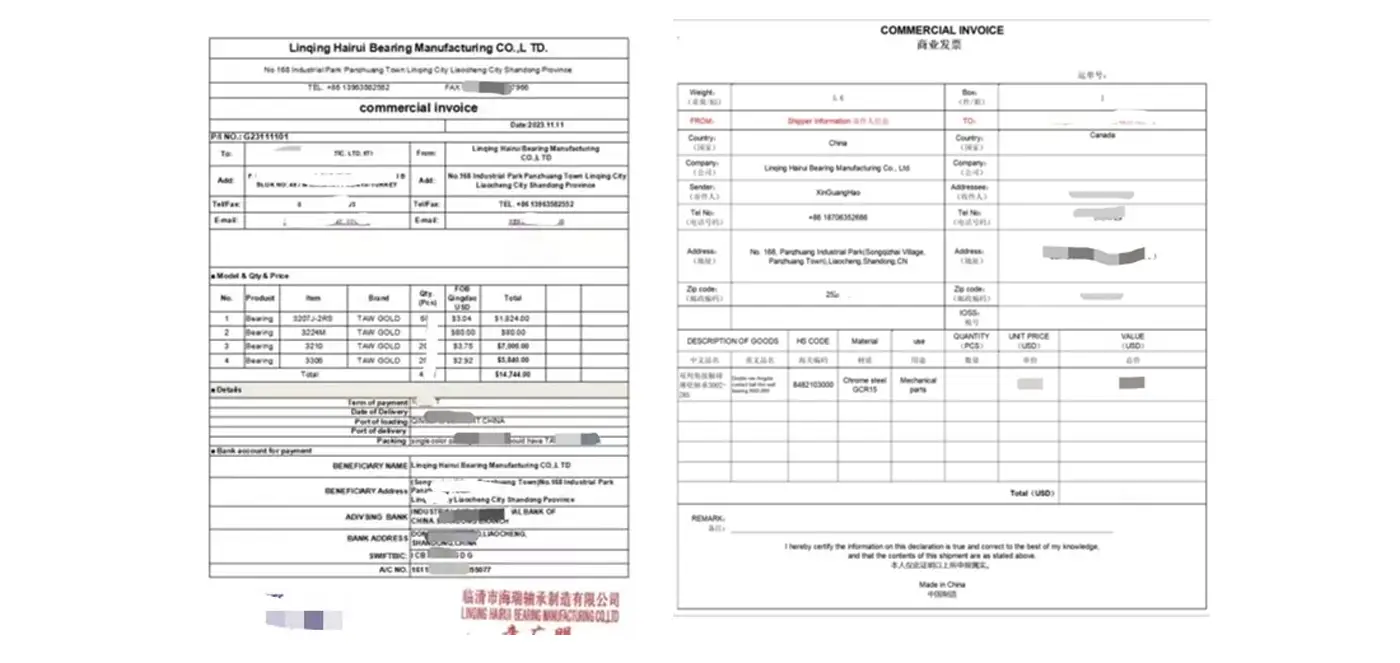

TRANSACTION CREDENTIALS

FACTORY

The company is located in Panzhuang Industrial Park, Linqing, with a total construction area of more than 30,000 square meters. The installation workshop and grinding machine workshop have been built to high standards, industry-leading production equipment and testing instruments have been introduced, and corresponding functional areas such as warehouses and dormitories have been equipped to create a first-class hardware environment.

Exhibition

The products have reliable quality and stable performance and are sold well in the national market and exported to Southeast Asia, Europe, South America, the Middle East and other regions. They enjoy a good reputation in the international market and have contributed the wisdom and power of Made in China to the development of global industrialization!

FAQ

Q: Are you a manufacturer?

Q: Can we visit your factory?

Q: Can you arrange the shipment?

Q: How long is your delivery time?

Q: How do you make our business long-term and good relationship ?

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

RELATED PRODUCTS

MESSAGE